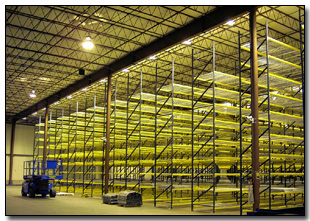

There are many pallet rack and shelving solutions available, each designed to be utilized with different  storage applications. Racking comes in a variety of sizes, capacities, and configurations. It can be used independently or linked to form an entire racking system.

storage applications. Racking comes in a variety of sizes, capacities, and configurations. It can be used independently or linked to form an entire racking system.

- Pallet Flow Rack

- Selective Rack

- Double Deep Rack

- Rack Supported Buildings

- Drive-in/Drive-Thru

- Carton Flow Rack Pick Systems

- Cantilever Rack

- Push Back Rack

- Pick Modules

- Radioshuttle Robotic Deep Lane Storage Pallet

When selecting rack and shelving, it’s vital to consider the physical characteristics of your product, such as:

- Weight

- Size

- Packaging

- Height

- Method of loading and unloading

A static pallet rack is the most common form of storage but comes in multiple configurations to address the application parameters. Though a single selective rack is still the most common in that it provides accessibility to all your pallets, double deep, push back, and robotic deep lane storage are often excellent alternatives. Double deep is best applied when you typically have more than one pallet of the same SKU, and storage density is top of mind. For applications with multiple pallets of the same SKU, push back is a simple solution for increasing density. At the same time, the popularity of deep lane robotic storage has grown exponentially because it can provide such a compelling ROI.

Equally important, however, are non-physical considerations. The product’s popularity is essential in that highly active product must be stored in such a way that it is readily accessible and in sufficient volume to meet activity requirements. The unique product must always be accessible since it is the only SKU of its kind in a given facility, whereas multiple loads of the same SKU do not require that all loads be readily accessible.

Lastly, the storage and picking methodology affects the storage mediums. Product stored in a forward pick  area will typically use a different storage medium than product used as backup storage. Forward pick areas have high degrees of picking activity, so the storage medium must complement that. Backup storage tends to be handled in larger unit volumes and, therefore, has lower and different storage needs.

area will typically use a different storage medium than product used as backup storage. Forward pick areas have high degrees of picking activity, so the storage medium must complement that. Backup storage tends to be handled in larger unit volumes and, therefore, has lower and different storage needs.

![]() Please contact us for help selecting the best warehouse pallet racking and industrial shelving options for your unique application, space, and operational requirements. Abel Womack also provides pallet rack installation, removal, relocation, reinstallation, and rack repair services.

Please contact us for help selecting the best warehouse pallet racking and industrial shelving options for your unique application, space, and operational requirements. Abel Womack also provides pallet rack installation, removal, relocation, reinstallation, and rack repair services.

storage applications. Racking comes in a variety of sizes, capacities, and configurations. It can be used independently or linked to form an entire racking system.

storage applications. Racking comes in a variety of sizes, capacities, and configurations. It can be used independently or linked to form an entire racking system.