In the material handling and warehousing world, forklifts play a crucial role in moving heavy loads from one place to another. However, their power and utility come with inherent risks. Forklift accidents can lead to serious injuries and even fatalities. Over the years, significant advancements have been made in forklift safety technologies to address these safety concerns. This blog will explore some of the latest innovations and how they enhance workplace safety.

with inherent risks. Forklift accidents can lead to serious injuries and even fatalities. Over the years, significant advancements have been made in forklift safety technologies to address these safety concerns. This blog will explore some of the latest innovations and how they enhance workplace safety.

- Collision Avoidance Systems

One of the most significant safety innovations in forklift technology is the development of collision avoidance systems. These systems use various sensors, cameras, and radar to monitor the forklift’s surroundings and detect potential obstacles, including other vehicles, pedestrians, and obstructions. When a potential collision is detected, the system can alert the operator through alarms and flashing lights. Raymond will soon be tying this into their iWAREHOUSE® offering, so it can even apply automatic braking to prevent accidents. Raymond calls this FieldSense.

and radar to monitor the forklift’s surroundings and detect potential obstacles, including other vehicles, pedestrians, and obstructions. When a potential collision is detected, the system can alert the operator through alarms and flashing lights. Raymond will soon be tying this into their iWAREHOUSE® offering, so it can even apply automatic braking to prevent accidents. Raymond calls this FieldSense.

- Forklift Speed Limiters

Speed limiters are another vital safety technology for forklifts. These devices help control a forklift’s maximum travel speed, reducing the risk of accidents caused by high-speed maneuvers. Speed limiters can be customized to match the specific needs of a facility and the type of forklift in use, ensuring a balance between productivity and safety. When paired with Raymond’s iWAREHOUSE system, speeds can be set universally for shifts or by the individual operator, which follows them from machine to machine. Many of our customers with iWarehouse set their new operators to a slower training speed and allow their more seasoned veterans to travel at full speed. They also often temporarily limit speeds for an operator that has had an incident.

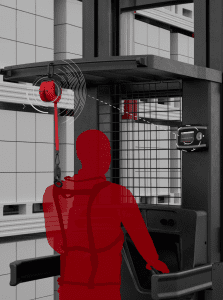

- Operator Monitoring Systems

Operator monitoring systems use sensors and cameras to track the operator’s behavior, including their posture, attentiveness, and use of seatbelts. If the system detects unsafe behavior, it can issue warnings or notify supervisors if equipped with additional hardware. These systems promote safety and provide valuable data for training and improving operator performance. For example, The Raymond Corporation introduced the Integrated Tether System, a first-of-a-kind operator assist tool designed to alert operators and managers and limit lift truck functionality if an operator is not correctly tethered on a ‘man up’ forklift. Raymond Introduces Industry’s 1st Wireless Integrated Tether System.

detects unsafe behavior, it can issue warnings or notify supervisors if equipped with additional hardware. These systems promote safety and provide valuable data for training and improving operator performance. For example, The Raymond Corporation introduced the Integrated Tether System, a first-of-a-kind operator assist tool designed to alert operators and managers and limit lift truck functionality if an operator is not correctly tethered on a ‘man up’ forklift. Raymond Introduces Industry’s 1st Wireless Integrated Tether System.

- Automatic Fork-Leveling Systems

Forklifts equipped with automatic fork-leveling systems ensure that the forks are always at the correct height and angle for safe lifting and carrying of loads. This technology prevents accidents and damage caused by improperly positioned forks, making it easier for operators to focus on their tasks.

- Improved Ergonomics

Ergonomics is essential for operator comfort and safety and modern forklifts are designed with this in mind. Features like adjustable seating, easy-to-reach controls, and improved visibility help reduce operator fatigue and minimize the risk of accidents caused by operator error. Raymond designs their forklifts with ergonomics as a focal point, and if you would like more information on this topic, please see our white paper here.

- Integrated Telematics

Telematics technology has made its way into forklifts, offering real-time monitoring of the equipment’s performance, location, usage, and impacts. This data can be analyzed to identify patterns and potential safety issues, helping companies proactively enhance safety and efficiency. These systems can also prompt operators to go through their daily checklists, and if an issue is noted, the maintenance department or the servicing dealer can be notified in real time. Raymond calls this suite of software- iWarehouse, as in intelligent warehouse.

Boost Warehouse Productivity and Safety

Forklift safety technologies have come a long way in ensuring the well-being of workers and improving the efficiency of material handling operations. These innovations, such as collision avoidance systems, speed limiters, operator monitoring systems, automatic fork-leveling, improved ergonomics, and telematics, all contribute to a safer working environment.

As technology continues to evolve, we can expect further advancements in forklift safety, enhancing the protection of both workers and valuable inventory. By investing in these technologies and providing proper training, companies can reduce the risk of accidents and create a safer, more productive workplace.

Leave a Reply

You must be logged in to post a comment.