Are you ready to stop reading just because of the title? Give me 30 seconds.

Would you look to upgrade your car, computer or phone without knowing the difference between what you have and what you want? What if the seller of your next purchase said there are functionalities or capabilities in your existing product that have yet to be used? What if you or the seller discovered you were not using your current product as efficiently as possible?

While the potential seller might not use your existing product as often as you might, there are pieces of information (data) that help understand if you’re using the product correctly and what the next upgrade should be.

THIS IS THE BENEFIT OF DATA!!

To quote famous NY rapper Jay-Z (and likely others): “Men lie, women lie, NUMBERS DON’T!” (emphasis mine)

I’ve applied this line to nearly everything in life, but, most importantly, I’ve used this saying to tasks, processes, and operations that do not require feelings – like running a warehouse.

Optimal Layouts and Operational Flows Come from Good Data & Software

As we discussed in Warehouse Best Practices – Part I, it’s good to understand what products you have (amongst other things) and how to handle these items efficiently within your current space.

The “good to knows” we discussed:

KYP2 – Know Your Product(s)/Personnel

KYL – Know Your Layout

KYC – Know Your Customer

However, one of the best ways to “know” the items listed above is to back it up with data. You can say, “I have customers in NY and CA,” but to know NY represents 70% of your business compared to CA’s 5% is a much more productive way of KYC-ing – knowing your customer. This is the same for KYP2 and KYL.

…So, how do we “know” these items listed above help with operational layouts and flows?

DATA, DATA, DATA!!!

Yes, data is a sexy word in itself… I know. Stay with me here.

Good Data – the kind that is quantifiable and measurable.

Quantifiable – we can evaluate operations or processes based on numbers for our purposes.

Measurable – is the ability to apply a metric or comparison from a base value (numbers).

To help us understand the difference, imagine an operator taking 3,000 steps over their shift. 3,000 is a number, which makes it quantifiable. However, suppose we have the same operator performing the same tasks over two days. On the first day, the operator covers it in 3,000 steps, and on the second day covers the same tasks in 1,500 steps. In that case, that’s measurable because it allows for comparison. This is how the industry has come to understand KPIs – Key Performance Indicators, which is just an understanding of (good) DATA.

quantifiable. However, suppose we have the same operator performing the same tasks over two days. On the first day, the operator covers it in 3,000 steps, and on the second day covers the same tasks in 1,500 steps. In that case, that’s measurable because it allows for comparison. This is how the industry has come to understand KPIs – Key Performance Indicators, which is just an understanding of (good) DATA.

A KPI is the ability to take key indicators and evaluate performance. In other words, KPIs help understand how well something is working.

Insufficient data – for the sake of comparison, the operator took 3,000 steps, but only 2,000 were used to perform business operations, and the other 1,000 were for walking around the building during lunch for exercise. If we’re not careful about the numbers used for measuring data, we can end up with numbers that DO lie (wrong data).

Good Software – the kind that reads good data and provides better data or information

Put simply, good software is only as good as the data it receives.

Numbers are emotionless. Accurate numbers provide good data – though data is emotionless. This is why numbers don’t lie and CAN’T lie. Note: Be as accurate as possible upfront; good data will guarantee saved time later.

Optimal Layouts and Operational Flows

This is NOT the part where I help you understand your facility’s best layout and operational flow. That’s impossible – unless you’re an existing client, and we’ve likely already discussed phases to efficiency and the right automation.

Optimal Layouts

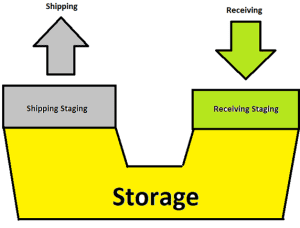

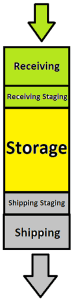

I can tell you that there are two most common warehouse setups: U-shaped and I-shaped. Depending on your operations, it would usually fall into one of the two if your facility’s overall shape allows it.

They would function exactly as their names suggest:

There are several ways to understand if your facility is made for one layout design. One way to understand the difference is based on dock door locations and the facility’s space to perform daily operations. A better way is to allow your material handling integrator to help you lay out your facility optimally and run your operations efficiently. Note: Abel Womack offers Lean Management Consulting and Automation Consulting to assist.

Operational Flows

As warehouse best practices go, we can begin looking at operational flows once we’ve started to paint a better picture of our optimal layout. Note: The optimal layout may change over time as operational flows change or grow.

This “flow” is dictated by data, meaning you need an accurate picture of product flow through your facility as represented by numbers and designations. To do this, we start with naming areas.

Naming Areas (designations)

From the design layouts above, we can see that most operations would involve similar steps:

- Receiving – the space allotted for pulling items from containers and trucks.

- Receiving Staging – the space allotted for organizing received items before storing.

- Storage –the space for… you guessed it! Storing items.

- Manifest – space is typically for packing, weighing, and labeling items before Shipping Staging.

- Shipping Staging – space allotted for organizing outbound items.

- Shipping – space for putting outbound orders into containers or trucks/vans.

You may have a few, all, or even more areas within your facility to ensure adequate operational flow. Naming the areas is the first step to getting organized, which is a key warehouse best practice. Once we have enough areas named, be sure to have identification numbers for your items. These would typically be considered SKUs or Stock Keeping Units.

Individual SKUs allow us to collect data in an Excel spreadsheet, homegrown WMS, or commercial software. It brings us full circle to how we started this article…

“Men Lie, Women Lie, Numbers Don’t!”

As a recommendation, get as many numbers as possible for everything you have:

- Facility Numbers

- Size of your warehouse, size of named areas

- Number of hours in operation per day, month, year

- People Numbers

- Number of employees per named area

- Number you’re paying each employee, fully loaded

- Item Numbers

- Start with SKUs and identify each item

- Determine the dimensions and weights of each item and store that somewhere (digitally)

- Order Numbers

- Per year, month, day, even hour would help

- Average and peak number of lines per order

- All the Numbers… because (good) numbers don’t lie!

To keep you awake, I’ll end the numbers game there. Please keep in mind there are companies ready to assist you and can offer free consulting or at least complimentary lean management walkthroughs.

With or without any external partners, Warehouse Best Practices Parts I & II should give you enough information to optimize your facility and prepare for the next phase in automation. However, we always recommend involving your local integration partner as soon as possible to ensure the proper steps are taken to optimize before you automate your business. After all, the reason for our business is to help your business.

Leave a Reply

You must be logged in to post a comment.