As a Raymond Solutions & Support Center member, the industry’s only 100% integrated network of material handling solutions experts, Abel Womack leverages exclusive partnerships across Raymond and its parent company Toyota Industries Corporation (TICO).

As part of TICO’s advanced logistics division, Abel Womack brings world-class automation, distribution, and production solutions from Bastian Solutions, a Toyota Advanced Logistics company.

Through this exclusive relationship, Abel Womack expands its offerings and meets your need as a total solutions provider. Regarding truck loading, ULTRA BLUE is one of those offerings that provide maximum productivity.

The Comprehensive Solution for Fluid Trailer Loading: ULTRA BLUE® Automated Robotic Truck Loader

Floor or fluid trailer loading is a common task that companies utilize to maximize the cube utilization of a trailer. Unfortunately, the improved usage of shipping space comes with an increased operational cost. At its core, fluid loading is an extremely labor-intensive task that has proven to be difficult to complete and staff. The work environment, ergonomic strain, and monotony of the task lead to high turnover rates and a physically strained workforce. Not to mention the increased costs and reduced throughput resulting from cases being double handled. Fortunately, Bastian Solutions has addressed these issues with the ULTRA BLUE® robotic truck loader.

The ULTRA BLUE is a reliable, innovative automation solution that supports high volume, fluid loading operations of cases with consistent footprint dimensions. Designed to be a turnkey system, this mobile robot can immediately improve throughput, working conditions, and customer satisfaction upon implementation.

A Single Solution for Maximum Productivity

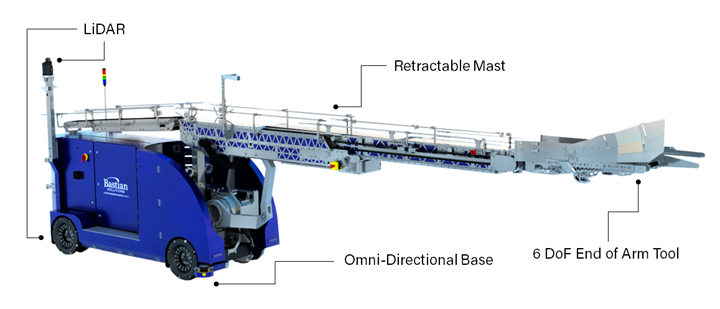

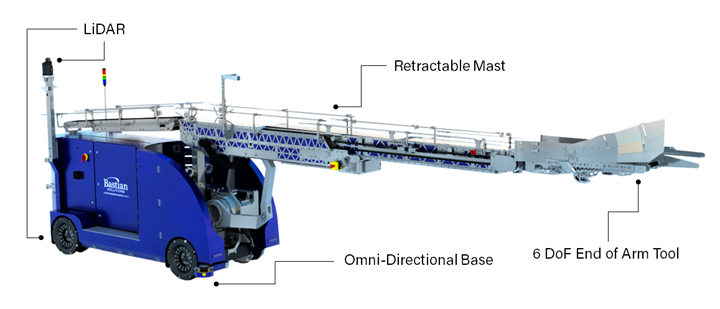

Unlike other loading systems on the market, the ULTRA BLUE merges several capabilities into a single, powerful solution. This unique solution combines a retractable mast, six degrees of freedom end of arm tool, and articulating conveyors to transport and place cases inside truck trailers quickly.

The culmination of these technologies gives the ULTRA BLUE the necessary reach and mobility to position boxes safely and accurately at rates faster than manual processes.

A combination of navigational methods, including LiDAR, offers precise localization in the truck and the docking area. The ability to travel in and out of trailers without the need for operator supervision or costly infrastructure improves output and ROI. Additionally, the omni directional base allows the ULTRA BLUE to move between dock doors, allowing a single unit to service multiple doors.

Smarter, Automated Outbound Operations

Other automation technologies can be paired with the ULTRA BLUE to fully automate the tasks upstream of the dock doors. This includes but is not limited to conveyor systems, sorters, robotic depalletizers, and AS/RS (automated storage and retrieval systems). This integration allows for the reallocation of workers to higher value add operations, reducing injuries associated with manual loading.

Loading Methods

The ULTRA BLUE can handle two different loading methods to fit your current outbound operations – consistent row loading and variable height loading. Consistent row loading processes walls of cases that are the same size, while variable height loading processes cases with the same length and width but variable height. Between these loading methods, this mobile robot can handle light to heavy cases that are taped, lidded, or folded.

Mobile Design

The ULTRA BLUE loader’s unique infrastructure-free and mobile design supports 24/7 automated operations in both brownfield (existing) and greenfield (new) facilities. This all-in-one product can solve many challenges facing companies today, including labor availability, freight costs, inventory tracking, safety concerns, and adaptation to future operational demands.

Transformative Technology and Industry Experts

Already have an idea of how an automated truck loader could meet your automation plans? Contact our team today to discuss how the ULTRA BLUE loader can help you meet your long-term goals!

Author: Trent Wideman

Original content posted on Bastian Solutions.

Leave a Reply

You must be logged in to post a comment.