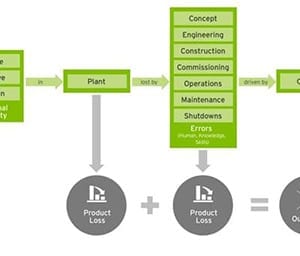

Clive Ross, Aurecon Group Aurecon’s Head of Asset Management, Clive Ross, says manufacturers can enhance their success by creating a proactive asset management culture and taking a more sophisticated approach to maintenance that optimizes asset performance and value. Hardwired in the psyche of manufacturers is the constant vigilance on total production cost. Sometimes, deferring or minimizing maintenance results in cost savings. However, these incremental savings are typically false economy. A strategic asset management approach can create far greater value for the business. Focusing on asset uptime availability and equipment peak operating efficiencies yields substantially more value than driving maintenance costs down. This value is at times less visible and tangible without a detailed knowledge of asset value creation. Over the past two decades, the world has experienced an unprecedented demand for raw materials products and processed goods. As a result, manufacturing plant, production facilities and many ancillary infrastructure assets have been pushed to limits well beyond their initial design specifications. Our urgency to get more from less has brought many facilities to breaking point. Maintenance of the asset, a cost not directly linked to productivity or revenue generation, is often deferred or worse, ignored. Organizations will take a range of approaches to asset management with varying results: 1. Measured and controlled asset debottlenecking exercises and asset efficiency design upgrades through sustainable work capital programs. These programs generally result in engineering standard and legislative compliant designs and production optimized assets that will continue to deliver enhanced production throughputs in future years. 2. Fast track projects that deliver immediate returns and enable the asset owners to capitalize on the demand experienced during these years. While these programs generally comply with the engineering design and legislative requirements, many are not optimized, and deliver suboptimal performance and efficiency. 3. Increased production throughputs via existing assets, […]

Leave a Reply

You must be logged in to post a comment.