First, what’s a Vertical Lift Module (VLM)? A VLM is a high-density, automated storage device. It is used for several purposes, one of the most common being to reduce the floor space required for storage. VLMs are also used to improve the throughput, control, and accuracy of parts storage, parts picking, or both operations.

of the most common being to reduce the floor space required for storage. VLMs are also used to improve the throughput, control, and accuracy of parts storage, parts picking, or both operations.

Endless storage solutions

VLMs are commonly used by manufacturers, distributors, and labs in the aerospace, electronics, and biomed-tech industries, but their applications are endless. VLMs generally store a wide range of inventories, including:

- raw materials

- work-in-process

- finished goods

- kits

- spare parts

- retains

- samples

- tooling

- maintenance-related materials

- supplies

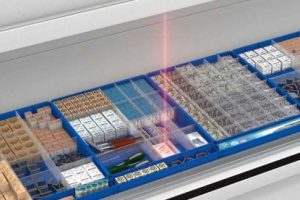

A key feature of VLMs is their use of “trays” to store goods. These trays are available in various sizes, but 96”x34” is the most popular. They are securely stored within the machine and delivered to the operator upon request. Once the operator (or picker) has picked or replenished materials on this tray, it is returned to internal storage and another tray can be delivered. This “Goods-to-Picker” approach improves ergonomics, with the tray delivered to the picker at waist-height compared to walking aisles of shelves, possibly stairs, and making difficult reaches for goods in high or low locations.

popular. They are securely stored within the machine and delivered to the operator upon request. Once the operator (or picker) has picked or replenished materials on this tray, it is returned to internal storage and another tray can be delivered. This “Goods-to-Picker” approach improves ergonomics, with the tray delivered to the picker at waist-height compared to walking aisles of shelves, possibly stairs, and making difficult reaches for goods in high or low locations.

Get ready to reclaim space

One key advantage of VLMs is their ability to recover floorspace through automation and the utilization of vertical space in the facility. Since VLM’s can be designed to fit just under your clear ceiling height, as high as 70’, you can store much more product than shelves or mezzanines. In optimal conditions, a VLM solution can reclaim up to 85% of the floor space currently used for storage. This significant space recovery can be redirected towards more revenue-generating activities or additional storage, further enhancing productivity and cost-effectiveness.

Some VLMs store inventories that require perpetual access, such as an order replenishment or kitting operation. Others are used to store goods that need infrequent access, such as supplies or maintenance-related goods. For infrequent access, the VLM can be used out-of-the-box without any software. In these cases, the facility would track and record what has been put in the unit and where. A spreadsheet with the inventory and tray numbers could allow the picker to request the appropriate tray manually. For other applications, software can be employed to manage the inventory, location tracking and all inbound and outbound transactions. The software also helps to improve efficiency and control with functions like order processing, lot control, order batching, cycle counting, and much more. Interfacing with ERP systems can provide immediate reconciliation of transactions.

VLMs can be ordered with “Pick-to-Light” features. These are visual aids that point to spot in the tray that is to be picked, what part to pick and how many. These features improve the speed and accuracy of the process.

The combination of vertical storage, goods-to-picker, pick-to-light, and software results in a system that processes more orders per shift with fewer pickers and fewer mis-picks.

Versatility with VLMs

VLMs can be designed with multiple operator access openings. Sometimes, it’s helpful to have access in the front and the back, like when the room is along a wall of adjoining rooms, so both rooms have access. It’s also beneficial when the room spans multiple floors, where inventory can be accessed on each floor.

VLMs can also be designed for use in cooler, freezer and controlled atmospheres. This would be for use where stringent temperature, humidity or air-quality control is essential, such as in a lab or cleanroom. (See our recent blog about the cleanroom pass-through feature)

Abel Womack represents Kardex Remstar VLMs. If you want to learn how these systems can benefit your operation, request a free consultation with one of our sales specialists. We can help you configure a solution for your unique application and calculate the return on your investment.

Leave a Reply

You must be logged in to post a comment.