Successfully engineering and installing a space-saving Kardex Remstar system for a customer is the end goal of an account manager. Receiving a purchase order is just the beginning. There are many technicalities in determining what units and supporting software and delivery systems are best for which facility and the logistics of implementation. With sales cycles up to a year or more, numerous steps must be taken to achieve that goal and ensure a smooth and seamless integration.

more, numerous steps must be taken to achieve that goal and ensure a smooth and seamless integration.

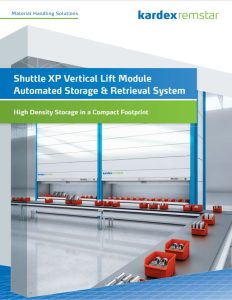

But let’s back up and talk about the benefits that help sell a Kardex unit. I’ll focus on a Vertical Lift Module (VLM) for the sake of this blog. Our primary focal points are improving storage density, accountability and accuracy of parts, faster pick rates, inventory security, and parts being picked in an ergonomically beneficial way.

VLM units can be sold in almost any industry under the sun. However, the application could completely differ from business to business in a specific sector. That said, engineering a Kardex system isn’t a cookie-cutter process. No account manager can diagnose which Kardex unit and associated systems are the best fit over a phone call. It would be irresponsible to accept an application without seeing the facility and understanding the customer’s requirements. Many factors must be considered.

Set up for success

Below, I outline six steps that need to be taken to ensure a smooth installation process.

- Conduct a site survey. First, getting eyes on the site and scoping out where units can be placed is imperative. The more vertical space, the better. The account manager must determine the best place to avoid beams, columns, and bar joists while also looking at sprinklers, HVAC, and ducts. After you find a potential spot, it is time to check the inventory to be stored and the in-out velocity of all SKUs. Chances are that the height of the inventory ranges greatly. While engineering a Kardex unit, we must select an average product height to configure how many trays we can fit inside the VLM.

- How can you transport these massive units into the facility? Kardex ships VLM units on big skids on 50-

foot trucks. Check the loading dock to ensure it is big enough to handle the units. Can a large truck fit on a tight block? Or do you need to change that shipment to two smaller trucks? It is essential to speak with the facility’s correct personnel about when the business receives shipments, their standard protocol, and how we will arrange delivery when the time comes.

foot trucks. Check the loading dock to ensure it is big enough to handle the units. Can a large truck fit on a tight block? Or do you need to change that shipment to two smaller trucks? It is essential to speak with the facility’s correct personnel about when the business receives shipments, their standard protocol, and how we will arrange delivery when the time comes. - Is this a first-floor installation? If not, be sure to measure the freight elevator or windows to ensure that the largest components can fit.

- How do we dispose of garbage? This must also be considered upfront. All those pallets and skids need to be disposed of, as well as a lot of plastic wrap and waste from the facility. Be sure to communicate with the facility on who is handling dumpster duties.

- Does the client want software to help operate the facility? Kardex can fully integrate ERP

through our excellent Power Pick Global software package. The opportunities and applications are endless. Get on the same page with the client regarding what they want the unit to do and how they want it to communicate with their ERP or WMS.

through our excellent Power Pick Global software package. The opportunities and applications are endless. Get on the same page with the client regarding what they want the unit to do and how they want it to communicate with their ERP or WMS. - If all these things have been addressed upfront, you still need a second pair of eyes. In my time at Abel Womack, I learned that humility can take you a long way. Luckily, we have a team of certified Remstar technicians with decades of experience who do an unbelievable job. Taking them to the site to sniff out any red flags avoids wasted time, money, and headaches.

Gaining insight

After all these steps are taken, we are just scratching the surface of what it takes to complete a successful job. However, if you can have your ducks in a row to start the process, you will be in good shape moving forward. Don’t get me wrong. Receiving a purchase order for a Kardex unit is great, but our end goal can’t be achieved without successful installations. Following these steps is an excellent way to ensure we can provide outstanding service to our customers, and it has allowed us to prosper for the last 100+ years!

Leave a Reply

You must be logged in to post a comment.