In today’s technology-driven environment, digital distractions are everywhere. Combine that with a fast-paced warehouse where heavy equipment operates constantly, and safety becomes more important than ever. The challenge is not just managing these risks. It is using technology to reduce them. That is where the Raymond iWarehouse® suite comes in.

Raymond’s iWarehouse solutions help today’s leaders implement cutting-edge safety technologies that support their teams and reinforce best practices. From controlling access to equipment to helping avoid collisions, Raymond’s technology is becoming the new standard in warehouse safety.

reinforce best practices. From controlling access to equipment to helping avoid collisions, Raymond’s technology is becoming the new standard in warehouse safety.

Strengthen the Fundamentals

A safe, efficient warehouse operation consists of trained operators, safe, well-maintained equipment, and real-time visibility into incidents and equipment usage. Raymond’s iWarehouse products address all these and more.

iWarehouse Telematics

The first step to overhauling safety in a warehouse comes down to a few key components.

- Ensure your operators are properly trained.

- Verify equipment is safe to operate.

- Have visibility into incidents so best practices can be reinforced.

The fundamentals of the iWarehouse system include:

- Access Control – Forklift equipment comes in a variety of shapes and sizes, each with unique controls and levels of risk.

The iWarehouse system utilizes badge-in technology, so only certified and authorized operators can use their facility badges to log into forklift equipment. This access control helps prevent someone not trained in driving equipment, reducing the risk of an incident.

The iWarehouse system utilizes badge-in technology, so only certified and authorized operators can use their facility badges to log into forklift equipment. This access control helps prevent someone not trained in driving equipment, reducing the risk of an incident. - Electronic Pre-Operation Checklists – Even if an experienced operator is at the helm, faulty hardware can be a recipe for an accident, making equipment inspections essential and an OSHA requirement. Manual paper-based checklists are cumbersome, a pain to store, and difficult to manage during an OSHA audit. Moving this process to the electronic iWarehouse system is a seamless way to ensure they are not only being completed but are safely stored and instantly accessible at the click of a button. You also can designate certain checklist items as critical. If it fails, equipment can automatically lock out from operation until repaired — helping prevent a safety risk before it happens.

- Impact Management – Even with the most rigorous of preparations, accidents happen. When they do, the iWarehouse system notifies supervisors instantly when an impact occurs. On compatible Raymond forklifts, the system can slow the forklift to 1 mph until a supervisor can inspect the vehicle and restore full speed. This immediate feedback helps leaders act quickly, provide valuable operations insights, and maintain safety standards.

Mitigate Risk and Maximize Uptime

Once you implement the iWarehouse telematics system, it opens a world of possibilities in the realm of safety technologies – giving operations leaders an unprecedented tool for mitigating risk.

operations leaders an unprecedented tool for mitigating risk.

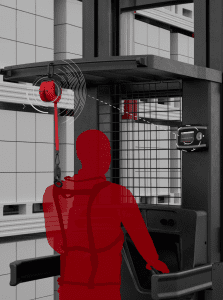

Take the integrated tether for example. iWarehouse connects with a wireless safety tether system for man-up lifts. When the operator is not safely tethered on a compatible Raymond forklift, the truck automatically stops the operator compartment from lifting and restricts travel speed to 1mph. Distractions happen, but technology used correctly can remind us that we need to prioritize safety.

Another great pairing with the Raymond iWarehouse system is a new product called ObjectSense™. By leveraging lidar installed on compatible Raymond forklifts, this system can detect objects in the trucks’ approximate travel path, including racking, pedestrians, and other vehicles. By dynamically adjusting its detection range based on vehicle speed and steering angle, ObjectSense can slow or stop the forklift before an impact occurs.

Harness Raymond iWarehouse Technology to Elevate Your Safety Standards

Leverage technology to take your company’s safety practices to the next level with Raymond’s iWarehouse suite of products. Contact your Abel Womack account manager today to learn how a customized iWarehouse solution can help protect your people, assets, and bottom line.

Leave a Reply

You must be logged in to post a comment.