The way a forklift operator operates their truck is of utmost importance to their safety and the safety of those around them. There are many critical considerations that forklift drivers and the companies that employ them need to be mindful of and provide appropriate training to ensure safety.

Driving forklifts safely and at proper speeds, and avoiding turning too sharply can significantly reduce accidents, collisions, and tip-overs. In turn, property damage, material damage, injuries, or even death also can be avoided. Certifying forklift operators and having them licensed is mandated by OSHA and will guarantee your operators know the rules of the road. Enforcing those rules and holding operators accountable for safe driving behavior is paramount in building a safe culture.

reduce accidents, collisions, and tip-overs. In turn, property damage, material damage, injuries, or even death also can be avoided. Certifying forklift operators and having them licensed is mandated by OSHA and will guarantee your operators know the rules of the road. Enforcing those rules and holding operators accountable for safe driving behavior is paramount in building a safe culture.

Essential things operators and companies need to be mindful of as it pertains to operating forklifts

Forklift Load Hazards

Loads must conform to the manufacturer’s limits, as every forklift has a maximum size and load they can lift. Lifting a load that is too heavy or an oversized load can significantly increase the chances of tipping over. This information is readily available on the manufacturer’s spec plate. Drivers must also properly secure loads prior to travel.

Pedestrians

Pedestrians and forklift operators need to be constantly aware of each other, as oftentimes, pedestrians are in the same area as forklift traffic. Serious injuries can occur if a pedestrian is struck by a lift truck. Facilities should have clearly marked pedestrian traffic lanes which can help minimize areas of overlap.

by a lift truck. Facilities should have clearly marked pedestrian traffic lanes which can help minimize areas of overlap.

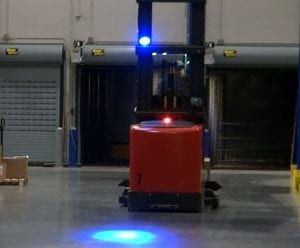

Many of our customers are starting to use a blue spotlight, which shines a light directly in front of the forklift, warning pedestrians that a forklift is approaching. Forklift drivers can’t always see in front of them due to bulky palettes, so having blue lights shine ahead warns both the drivers and pedestrians what is coming down the aisle so they can safely proceed.

Blind Spots

Blind spots cause additional issues for pedestrians and forklift operators. When a forklift is loaded, oftentimes, it is difficult for the operator to see going forward. Operators must take special care and be aware of their blind spots to minimize accidents.

Attachments

It is also imperative that attachments follow the manufacturer’s guidelines as they must be attached correctly. An improperly installed attachment can be a cause for failure and injury. All attachments should be certified by the manufacturer. There should be an additional spec plate attached to the forklift specifically for reference for the attachment’s limits and use.

All attachments should be visually inspected and checked prior to each use. Any malfunctioning attachment should be immediately removed from service, a service call made, and not used again until it is in proper working order. Utilizing attachments for something they are not designed for and manufacturer-approved for also can cause significant safety issues.

Floor Condition

The condition of the floor plays a critical role in forklift safety. Debris, including broken pallets, puddles, and broken concrete, all create unique challenges. Debris on the floor causes damage to forklifts and causes you to go through wheels very quickly, especially with pallet jacks. Puddles can cause a forklift to slide around corners and possibly create a dangerous situation as forklift wheels do not have tread. Most importantly, the condition of the floor is critical. The taller a forklift goes, the better the condition of the floor must be. If there is a pothole in the concrete and the forklift isn’t sitting evenly on the ground, the load will be tilting and can cause the forklift to tip. The safety concerns are greatly exaggerated the higher the forklift lifts.

Overhead Obstructions

Overhead obstructions in warehouses include heaters, gas and air lines, mezzanines, and doorways, to name a few. Operators always need to be aware of their surroundings and, before lifting, make sure they have a clear path above them. In some cases, adding visual warning signs can help.

to name a few. Operators always need to be aware of their surroundings and, before lifting, make sure they have a clear path above them. In some cases, adding visual warning signs can help.

Charging

Forklift operators must always be careful when charging electric forklifts. When charging batteries, hydrogen, a combustible gas, is released. You must always make sure to minimize the chance of sparks by ensuring chargers are stopped prior to disconnection, pulling connections apart by the connection, not the cable, and ensuring the areas are adequately vented. Cigarettes should never be in this area. Lastly, care should always be taken if the batteries are being changed, as some of these batteries can weigh several thousand pounds.

Don’t get overloaded!

Companies should work closely with their material handling provider to fulfill their forklift needs and help ensure safety for the team, regardless of industry. At Abel Womack, our team does walkthroughs with the customer alongside our safety trainer, to determine the limits for weights and load centers, and recommends the particular type of attachment needed.

If you need more information on common forklifts hazards, safety, or material handling solutions, please contact our specialists today.

Leave a Reply

You must be logged in to post a comment.