Why Adopt a Lean Management Approach?

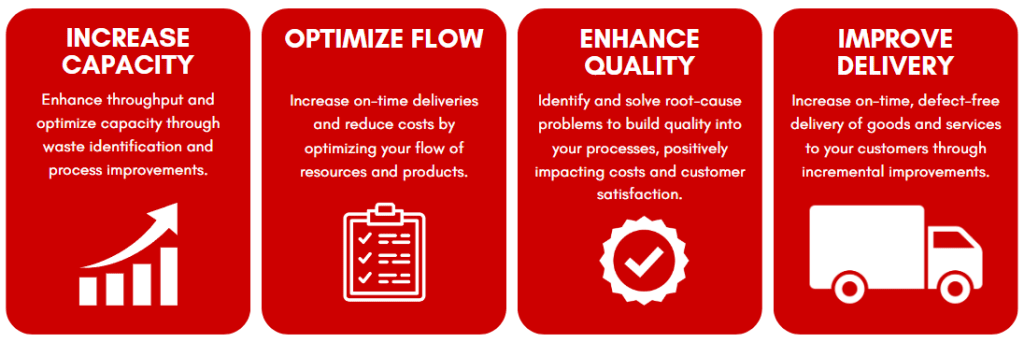

In warehousing facilities, even small enhancements in productivity and efficiency can have a big impact on your bottom line. Whether it’s through faster fulfillment, reduced waste, minimized downtime, or improved quality, operations are looking for any advantage at every turn.

impact on your bottom line. Whether it’s through faster fulfillment, reduced waste, minimized downtime, or improved quality, operations are looking for any advantage at every turn.

Built on the proven foundation and principles of the world-renowned Toyota Production System (TPS), Raymond Lean Management is a holistic approach to problem-solving. It allows you to focus on waste reduction through visualization, standardized work, track key performance indicators, and make continuous improvements to provide the best solution possible.

Proven Practices to Improve Quality & Optimize Operations

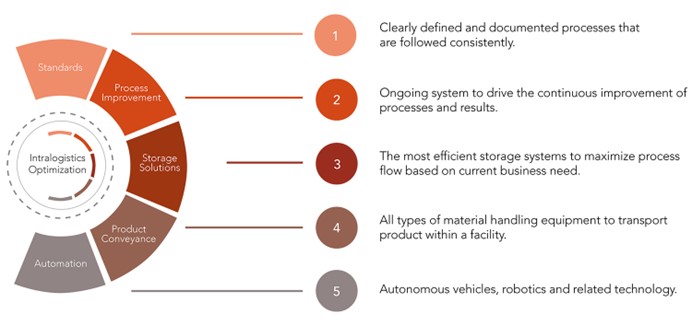

Understanding and applying efficient processes is crucial to your everyday efficiency and overall success. Raymond’s Lean Management System gives you a variety of tools, training, and resources to identify and remove inefficiencies and create measurable standards for improvement.

Raymond’s Lean Management System is designed to help your people work more securely and efficiently.

Through a proven process of visualization, organization, and standardization, we’ll show you how to identify inefficiencies and implement changes designed to improve your workflows and save you time and money. Our goal is not just to help you solve problems but to teach you how to solve them yourself.

Lean management adds value by empowering your workforce to make improvements, take ownership of daily tasks, identify inefficiencies or potential errors, and solve for waste. These practical tools to share ideas and develop impactful, long-term solutions create organizational changes resulting in a more engaged culture and higher morale and retention.

Lean management adds value by empowering your workforce to make improvements, take ownership of daily tasks, identify inefficiencies or potential errors, and solve for waste. These practical tools to share ideas and develop impactful, long-term solutions create organizational changes resulting in a more engaged culture and higher morale and retention.

Create an Optimized Workplace

Learn more about proven practices to get the most of your current resources and instill a culture of continuous improvement.

Download Your Free White Paper on Lean Management Principles

Contact us to see how lean practices could maximize operational efficiencies and productivity across your entire organization.