The costliest process in most warehouses is the picking operation. That’s because picking requires lots of labor, and labor is expensive. If you want to save money in your warehouse or distribution center — and who doesn’t? — a great place to start is to analyze your slotting methods. If you can reduce the amount of labor required to pick a day’s orders, you’ve just increased your bottom line.

The theory behind slotting is simple: Put the things you need most often in the most reachable locations. This is where data comes into play. You need to know what you have to store, how often the stored items are accessed, and the storage area available. Let’s take a look at how to categorize the items and where they should be stored in the warehouse. In a future blog, we’ll dive into profiling and examine how that process can reduce the amount of air you store, increase storage capacity, and reduce lost profits.

Slotting items is as easy as A, B, C

To determine the classification of each item, let’s break them down into A, B, and C categories based on how  quickly the items move. Review each of your SKUs and place them into one of these classifications:

quickly the items move. Review each of your SKUs and place them into one of these classifications:

- The SKUs with the greatest velocity, or movement, should be considered ‘A’ items. In line with Pareto’s Law, these SKUs typically account for 80% of the picks, 20% of all inventory, and are considered fast movers.

- Second are the ‘B’ items. These typically account for 15% of the picks, and 30% of total inventory.

- Lastly are ‘C’ items, and although they only account for about 5% of all picks, they typically make up 50% of the inventory.

An ideal place to store your items

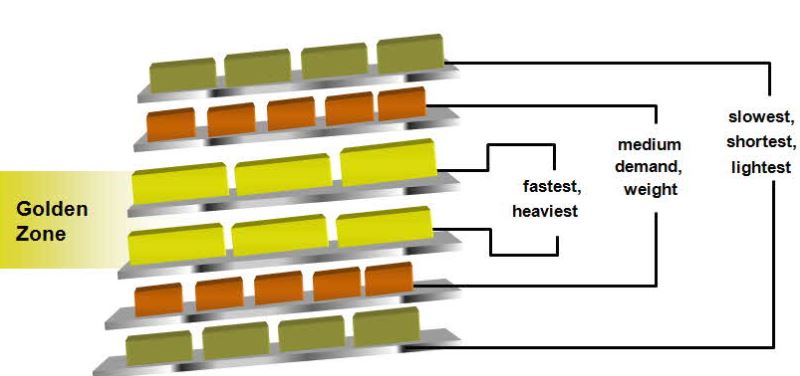

The forward locations of your shelving or racking, typically near the loading docks, are most often utilized for the fastest moving items in a warehouse. For instance, we put the ‘A’ items here, either at the lowest pallet position, or at the mid-level shelf.

The ‘B’ items are then located after the A’s, assuming a return pick route is used, followed by the C’s in the back. If using an S-pick route, consider the weight of each item to get heavy items at the bottom of the load so they can be picked first. Maintenance is also a crucial part of the plan. When a new SKU comes in, make sure it doesn’t get hastily put away in the “back 40” of the warehouse. If you aren’t slotting, you’re missing the boat!

Not sure where to start? Tools like Slot3D can help evaluate multiple data lines to select the perfect location for  each item.

each item.

If space is a concern, consider a second level order picker like Raymond’s Model 8720. These trucks offer the efficiency, simplicity, and speed gained by picking to pallet jacks while allowing access to higher shelf levels, thus expanding available pick faces.

Warehouse slotting solutions

Using a system like Slot3D, a slotting program that fully integrates with AutoCAD to streamline warehouse workflow, you can analyze the SKU size, weight and velocity, and determine the optimum storage location. Systems integrators offer tools like these to optimize your warehouse plans, capacity analysis, space and layout planning, equipment cost-benefit analysis, benchmarking and more.

If you are manually locating the items, simply list them in a spreadsheet based on picks per year in descending order (most to fewest). Both will help you plan out the slotting process and offer greater net gains than manually locating items.

The process of warehouse slotting in its simplest form only requires a bit of research, a spreadsheet, and a little extra work, but it can increase efficiencies and reduce travel time substantially – shrinking labor costs at the same time. If this feels overwhelming, don’t worry. Abel Womack has the tools and expertise to re-evaluate your warehouse slotting strategy to develop an efficient and well laid out facility.

Leave a Reply

You must be logged in to post a comment.