Many businesses are experiencing rising labor costs while also having a hard time finding and retaining enough qualified labor, including forklift operators and order pickers, for their warehouses. If you haven’t already, your company may soon be facing similar challenges.

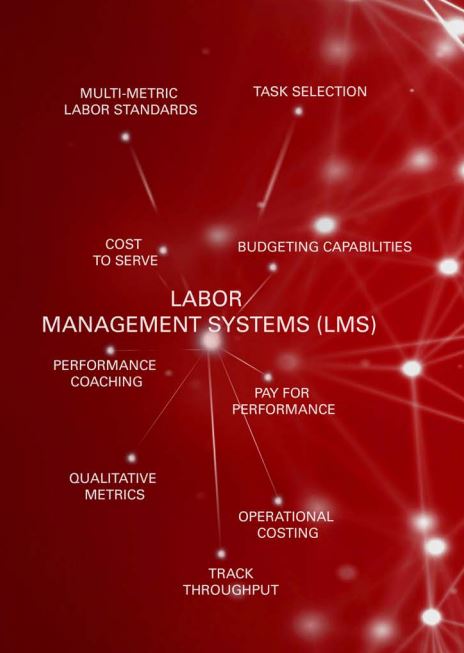

Labor is the largest controllable business expense, but it can seem tough to get your hands around where to make changes without better insight into what’s happening. Having visibility into these costs allows you to identify inefficiencies to act upon and change. Many warehouses still use time-consuming Excel spreadsheets to track labor or rely on traditional enterprise Labor Management Systems (LMS) that are typically over-engineered, too complex, and difficult to maintain in dynamic environments.

A High-Performance Partner

There is an affordable alternative to a costly enterprise LMS which requires software licensing, industrial  engineering, and implementations along with ongoing licensing and support fees. The alternative is a cloud-based system that doesn’t need expensive hardware or any systems administrators to manage or maintain. All that’s needed for this version is an internet connection and a web browser.

engineering, and implementations along with ongoing licensing and support fees. The alternative is a cloud-based system that doesn’t need expensive hardware or any systems administrators to manage or maintain. All that’s needed for this version is an internet connection and a web browser.

A cloud-based LMS can quickly and easily be integrated with a company’s fleet, including iWAREHOUSE telematics and Warehouse Management System (WMS). This seamless integration allows the LMS to constantly capture data from your WMS, time clocks, RF scans, ERP, CRM and more. Then, it runs all of this information through the software to provide visibility reports analyzing where your workforce dollars are being spent, and how to identify inefficiencies at every level of your operation – creating savings in labor, costs, and time.

More Time Relates to More Money

Integrating this kind of LMS can be a game-changer. Imagine finding 15-minutes of missing time per employee per shift: For two shifts, that is 2.5 hours per week per worker. For 50 workers per shift, that’s 125 hours of lost productivity per week- or almost $95,000 at $15/hour. By looking to eliminate the cause, LMS will pay for itself from the snap. If you’re currently paying a staffing company to track time, you can also bring everything in house with a cloud-based LMS for similar fees and so much more benefit.

Integrating this kind of LMS can be a game-changer. Imagine finding 15-minutes of missing time per employee per shift: For two shifts, that is 2.5 hours per week per worker. For 50 workers per shift, that’s 125 hours of lost productivity per week- or almost $95,000 at $15/hour. By looking to eliminate the cause, LMS will pay for itself from the snap. If you’re currently paying a staffing company to track time, you can also bring everything in house with a cloud-based LMS for similar fees and so much more benefit.

Benefits of Using an LMS

- Maximize employee utilization & productivity

- Drive out lost time

- Develop & implement standards & best practices

- Manage & motivate staff

- Pay for performance

- Control costs

- Increase margins

More Data Drives Better Decisions

Labor Managements Systems have a simple ROI calculator that takes complex data and translates it into quick, actionable analytics that shows substantial ROIs. Calculating total employee cost using metrics, including employee info; number of employees, base hourly wage, burden on wage, and annual wage rate increase can result in a reduction in missing time per employee, a reduction in indirect labor hours (%), and an increase in employee productivity.

quick, actionable analytics that shows substantial ROIs. Calculating total employee cost using metrics, including employee info; number of employees, base hourly wage, burden on wage, and annual wage rate increase can result in a reduction in missing time per employee, a reduction in indirect labor hours (%), and an increase in employee productivity.

More Efficient Use of Time

Enhancing employee productivity by eliminating wasted time can reduce your costs effectively. And, the ROI can be quite substantial. Don’t forget your time. If you have internal systems that require hours of your day to track employee time and efficiency, you can also increase your own productivity by putting an LMS to work.

If you’re interested in learning more about a cost-effective LMS and how it can help provide a complete picture of your fleet and warehouse operations, contact your material handling provider.

Leave a Reply

You must be logged in to post a comment.