We’re growing! We must go look for more space to lease, or better yet, let’s build!

I was sitting with a client the other day after being called in to design a layout for his new warehouse. He handed me paper drawings of the building and said “How many pallets can I get in this building?” I said, “I don’t know” and then I asked him “How many pallets do you need to store?” Then it was his turn to say, “I don’t know, as many as I can…” You get the picture!

Too many times in 27 years I’ve had this conversation. I ask myself, how can a successful businessperson lease a building, or worse yet, build a building without knowing what needs to be stored? How do you know the building is big enough? How high should the clear height of the ceiling be? How large a cubic volume do we need? Knowing that that expertise is our business and you have to concentrate on yours, here’s how to answer these questions!

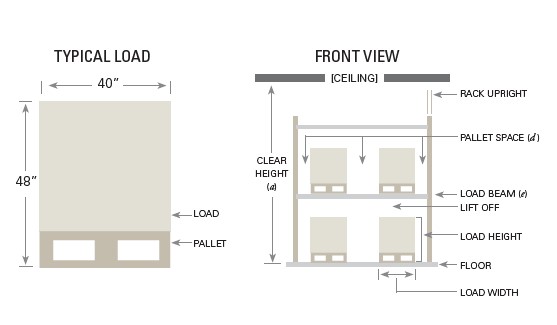

The good news is that it’s a straightforward process. Let’s start with the size of the load to be stored; YOUR loads. Ask your Warehouse Manager to give you the height, width and length and weight of your pallets. See the illustration below:

At this point, all you need to do is get the load dimensions. After you get those, determine the needed aisle size. This will vary depending on the type of forklift equipment that your operation uses. Typically, a sit down or stand up counterbalanced dock truck needs a 12’ to 13’ aisle. A reach truck requires about a 9’- 10’ aisle and a wire guided, swing-reach truck requires a 5 ½’ to 6’ aisle.

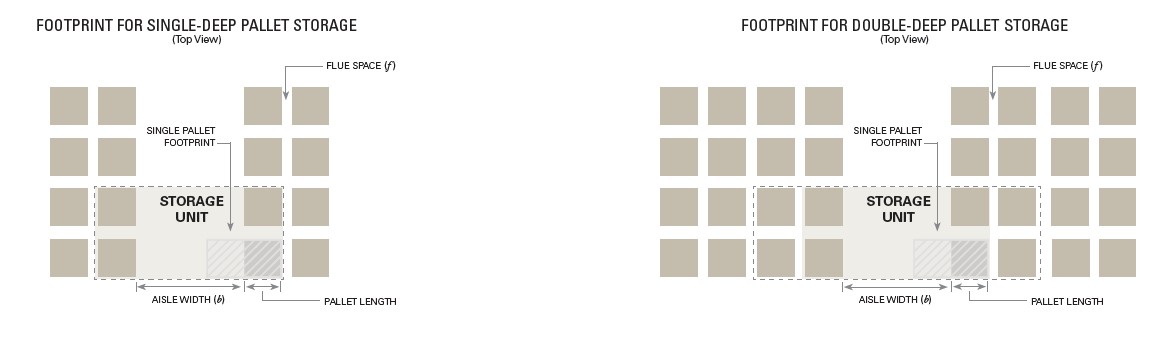

The reason it’s necessary to know your aisle size is to determine another of the variables for calculating the cube for pallet storage. See the illustration below:

By knowing the pallet size, the spacing around the pallet (sides and behind) and the aisle size, something called the “Storage Unit” can be calculated.

For standard, single deep pallet storage, add the depth of (2) pallets (usually 48”/pallet or 96”) + the aisle size (say it’s 108”) + the clear flue space between the rear of the pallet (usually 6”). If you add this all up, it comes out to a depth of 212”. That takes care of the depth. To calculate the width, add the width of (2) pallets + the space between the pallets (usually 5” or so) thus the space between the pallets and the pallet racking upright on either side (also usually 5” each). Add these together and you come up with a standard 96” space between the rack uprights. Lastly, add the width of one rack upright, usually 3” or 4” depending on rack height and weight to be stored, and you have 99”.

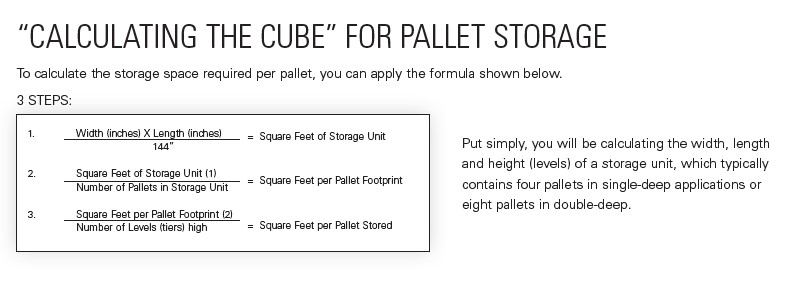

Now you have enough information to start solving the equation below.

Let’s use our example above:

1. Width in inches = 99 x length in inches = 212. 99 x 212 = 20,988 square inches.

There are 144” square inches in a square foot, so divide 20,988 by 144 = 145.75 square feet.

2. Take 145.75 square feet and divide by the number of pallets. Two in this case. 145.75/2 = about 73 square feet/pallet. But that’s for only one level. This is why you need to know the height of the pallet, the amount of lift off space and the height of the pallet rack load beam (see figure 1).

3. Just to complete the formula, let’s assume that you are storing 4 high in a 21’ clear building. Take the 73 square feet/pallet you just calculated and divide by 4. 73/4 = 18.25 square feet/pallet. If you had a 26’ clear building, you would have another level or 73/5 = 14.4 square feet/pallet.

So, how does this help? Now you have the tools to calculate the square footage required to store a pallet in a reach truck layout at a given height. Before going out with real estate agents, do some homework… Ask the question “How many pallets do I need to store?” Let’s assume we need to store 5,000 pallets and we want to stay in a 26’ tall building. That means 14.4 square feet/pallet that you just calculated. 5,000 pallets x 14.4 square feet/pallet = 72,000 square feet!

But wait, that’s not all! There needs to be a comfortable staging area for inbound and outbound freight, an office, bathrooms and some wasted space. Figure an additional 30%-35%. 72,000 x 135% = about 97,000 square feet. Now you KNOW how large a building to look for at a given height.

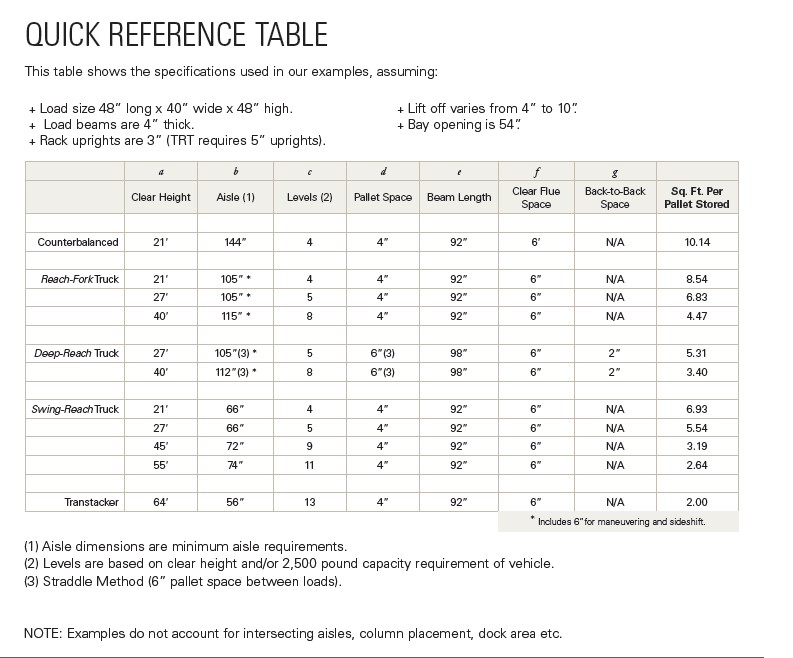

The last table below is a “rule of thumb” Quick Reference table. As noted at the bottom of the table, it does not take in to account intersecting aisles, column placement, dock area etc.! Also, the authors of the table are using 92” long load beams, not the standard 96”. With that said, I find this chart very useful. If you need any help with your warehouse calculations and the impact of using different types of lift truck systems on your building size and operation, Abel Womack is ready to assist you.

Leave a Reply

You must be logged in to post a comment.