More and more, customers are using forklift attachments to adapt their lift trucks to meet operational needs. But before doing this, it’s important to consider how the use of an attachment will impact the capacity rating of the forklift. Let’s dig into this and look at some numbers.

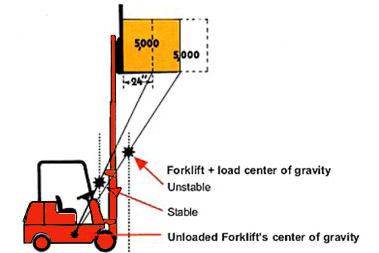

The key factor in determining a new load rating is how the use of the attachment changes the center of  gravity of the forklift. The load center is the distance from the face of the forks to the load’s center of gravity. A forklift’s load capacity is the maximum weight that a forklift is able to safely carry at a specified load center and a maximum load height.

gravity of the forklift. The load center is the distance from the face of the forks to the load’s center of gravity. A forklift’s load capacity is the maximum weight that a forklift is able to safely carry at a specified load center and a maximum load height.

Forklift capacities are based on the load center of whichever is longer: the load being handled, the length of the forks, or the attachment being used. For example, a 4,000-pound-capacity truck with a set of 42-inch long pallet forks handling a 48-inch x 48-inch pallet has a 24-inch load center – or half the length of a 48-inch long pallet (the most common size load handled).

If the same truck were to handle a load that was 60-inches long, the load center would then become 30 inches, and the truck’s capacity would down rate to 3,200 pounds. (4,000-pound base capacity x 24-inch design load center = 96,000 inch-pounds. Then divide 96,000 by the new load center of 30-inches for a down-rated capacity of 3,200 lbs.)

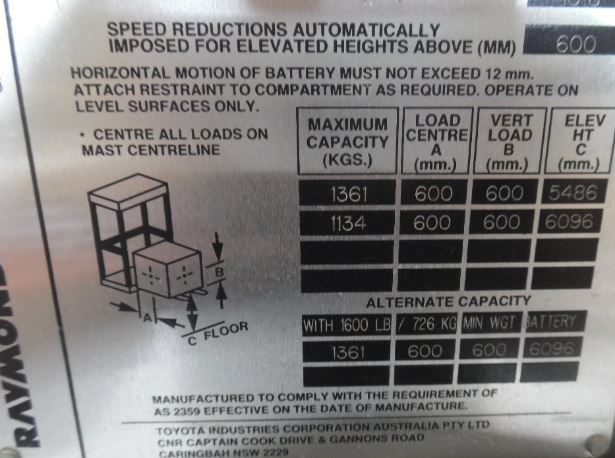

There are other factors affecting the down rating of the overall lifting capacity of a truck, including the weight of the attachment as well as its horizontal center of gravity (HCG) and vertical center of gravity (VCG). These should be considered when using carriage-mounted attachments like carton clamps, push-pulls and weigh scales.

According to OSHA, any forklift using an attachment or handling a load that has a longer load center  than the truck is rated for, must show an alternate capacity tag from the lift truck manufacturer. If the change in load center is not factored into the calculated lifting capacity, forklift safety can be compromised, leading to dropped loads, control issues and tipping. All of these can be dangerous and costly situations that can be minimized with knowledge, foresight, and planning.

than the truck is rated for, must show an alternate capacity tag from the lift truck manufacturer. If the change in load center is not factored into the calculated lifting capacity, forklift safety can be compromised, leading to dropped loads, control issues and tipping. All of these can be dangerous and costly situations that can be minimized with knowledge, foresight, and planning.

If you have any questions on the usage of forklift attachments, we’ll be happy to help or leave a comment below.

Leave a Reply

You must be logged in to post a comment.