Prior to COVID-19, using a conveyor system for packaging, sorting, receiving and picking was a smart move to reduce labor costs by reducing inefficient employee movement. However, with social distancing currently in place, a conveyor system now adds additional value by providing ample distance between workstations to move products safely throughout the warehouse.

There are many different scenarios for conveyor application depending on what you do. From simple, small, and less expensive solutions to large, more complex ones that fit your needs and create a compelling ROI. Below are some of the ways Abel Womack has helped our clients using conveyor systems.

Unloading shipping containers

Are you receiving unpalletized shipping containers daily? If so, then a manual accordion conveyor is  recommended.

recommended.

Normally it takes three to four employees to unload a container piece by piece, at approximately three to four hours per container, depending on size and number of pieces. Walking back and forth to unload is wasted labor, adding cost to your products (cost of goods).

Using an accordion conveyor in this situation, one employee in the container feeds the gravity accordion conveyor to another employee on the dock who stacks a pallet with the products. The ROI is two employees doing the same task as three to four employees in the same three to four-hour time frame.

Expandable conveyors also work well in truck loading and unloading, shipping areas, and loading docks. Additionally, implementing the required six feet or more for social distancing is possible in all of these applications.

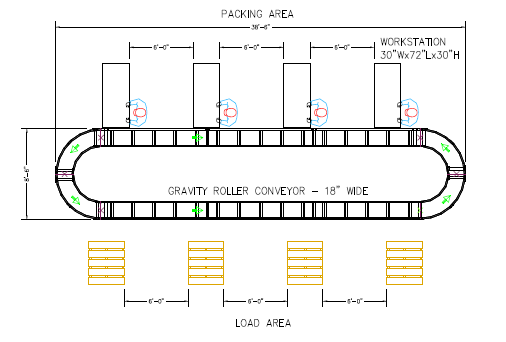

Moving product on packaging lines

Hytrol gravity roller conveyors on packaging lines accommodate workstations set six feet or more apart for social distancing. Each tote has a product that is ‘picked and passed’ between each station by pushing it along the conveyor. Gravity conveyors are an economical and versatile solution.

Automating picking process to gain total control with WMS

A powered conveyor system also can perform the tasks mentioned above with higher throughput and bigger returns on labor savings while supporting social distancing. These systems have capabilities that can include pick modules, mezzanines, sorters, diverters, and ancillary types of automation, to name a few.

A powered conveyor system also can perform the tasks mentioned above with higher throughput and bigger returns on labor savings while supporting social distancing. These systems have capabilities that can include pick modules, mezzanines, sorters, diverters, and ancillary types of automation, to name a few.

Incoming cartons are routed to their storage zones, completed orders routed to packing stations and completed labeled orders are routed by a WMS/WCS to shipping lanes. All of this will greatly increase your system-wide traceability, tracking, and productivity. In the right application, the ROI is often less than two years. We can finance these systems so you can be cash flow positive right out of the gate.

Supporting your need

With an experienced team of account managers, system engineers, and service technicians ready to support all your Hytrol conveyor needs, Abel Womack has you covered.

Many facility operations are reactive to the growing demand and popularity of increased inventory, rather than proactive. By proactively designing a highly optimized warehouse, operations not only save time and money, but can increase profit from the get-go.

Knowing about all the available options to help operations achieve this productivity is the largest part to making a fine-tuned machine out of your warehouse. Call the experts at Abel Womack today to get a detailed analysis of your current operation and how it can be optimized more efficiently.

Leave a Reply

You must be logged in to post a comment.