The future is changing, the economy is getting better, everyone wants their merchandise tomorrow, and there isn’t enough labor to meet this growing demand. Thankfully, even though the current labor market is quickly becoming saturated, new technologies are emerging at an even faster pace to mitigate this long-term problem.

For years you have hired additional people to meet increased demand and paid overtime to address seasonal peaks, sometimes even utilizing third party companies to assist with workload equalization. Now, just for a moment, picture in your mind what I’m about to describe and start thinking about your own application. Although potentially different, the concept may be similar.

Technology Comes into Focus

You enter a dimly lit distribution center and hear noise but see very few people. It’s kind of eerie but as you get closer you see a pallet of various sized cases. A robotic arm with a special tool at the end is picking these cases off the pallet, rotating the cases until a barcode is read, and then placing them on the conveyor. The conveyor then transports them to an area that has multiple high-speed cranes (mini-loads). These cranes take each case and randomly store them somewhere within this 30-foot tall x 100-foot-long enclosed storage system. You wonder, where are these cases going and how will I ever find them?

You enter a dimly lit distribution center and hear noise but see very few people. It’s kind of eerie but as you get closer you see a pallet of various sized cases. A robotic arm with a special tool at the end is picking these cases off the pallet, rotating the cases until a barcode is read, and then placing them on the conveyor. The conveyor then transports them to an area that has multiple high-speed cranes (mini-loads). These cranes take each case and randomly store them somewhere within this 30-foot tall x 100-foot-long enclosed storage system. You wonder, where are these cases going and how will I ever find them?  Then you notice cases coming out of this same unit being inducted onto a take away conveyor and transported to an area that now has a robotic arm palletizing these cases. But this time, the cases are being meticulously and accurately palletized to go to a specific customer or location.

Then you notice cases coming out of this same unit being inducted onto a take away conveyor and transported to an area that now has a robotic arm palletizing these cases. But this time, the cases are being meticulously and accurately palletized to go to a specific customer or location.

Wouldn’t that be cool? Well, all this technology is already here and available for your application.

Equipment that Handles these Activities

- Warehouse Management System (WMS) – absolutely the heartbeat of automation. Keeps track of your cases from start to finish.

- FANUC Robotics – the world’s leader in robotic applications coupled with a state-of-the-art vision system that allows for mixed case palletization and de-palletization.

- Conveyor – allows the transport of product from one area to another.

- Mini-load Systems – stores product automatically within an enclosed system. A bar code or RFID tag tracks the location and quantity of everything stored.

This approach is quickly becoming mainstream, as it is proven technology and often with a compelling ROI. Not only are you addressing this growing problem of a shortage in qualified labor but you are eliminating the drudgery and injury possibilities associated with people doing repetitive lifting.

The Path to Innovation

Remember, this equipment can be used in many ways, not just for what I’ve outlined. A robot can  be used for in-process applications such as picking specific products off a conveyor and placing items into a tote or onto a product sorter. They also can be used for simple end-of-line palletization. An example would be to palletize bags of pellets, ice, grain or maybe even fill empty boxes with product.

be used for in-process applications such as picking specific products off a conveyor and placing items into a tote or onto a product sorter. They also can be used for simple end-of-line palletization. An example would be to palletize bags of pellets, ice, grain or maybe even fill empty boxes with product.

If you pick eaches out of cases, the mini-load is perfect. Simply download a pick list and the mini-load crane will go get that case for you, and return it once completed. It does all of this in the most efficient way, by bringing goods to the picker.

Maybe you deal with pallet loads. It’s the same general concept of storage but the system deals with pallets instead of cases.

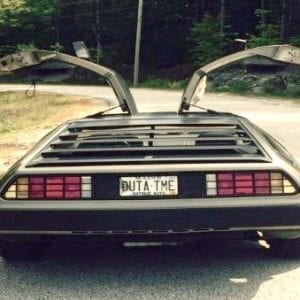

Don’t Run Out of Time

Now you see how automation can help your organization, has the flexibility to run 24/7, if needed, and should allow for a much more controlled and satisfied labor pool. This will allow you to meet the ever-growing demand while saving you money. And that eerie feeling you initially had will soon turn into a sound that you’ll look forward to everyday.

Now you see how automation can help your organization, has the flexibility to run 24/7, if needed, and should allow for a much more controlled and satisfied labor pool. This will allow you to meet the ever-growing demand while saving you money. And that eerie feeling you initially had will soon turn into a sound that you’ll look forward to everyday.

You still have time!

Well Done Mr. Rick. Compelling read and very thought-provoking.

Thx for sharing!