In a world driven by data, why cut yourself short when it comes to fleet management and operator safety? There has been a recent uptrend in companies looking for more data and control over their forklift fleet and how it’s being used. Whether it be controlling who uses what equipment, getting notifications when someone drives into something, or determining if a truck is worth fixing versus replacing, iWarehouse gives companies unparalleled control and visibility.

companies looking for more data and control over their forklift fleet and how it’s being used. Whether it be controlling who uses what equipment, getting notifications when someone drives into something, or determining if a truck is worth fixing versus replacing, iWarehouse gives companies unparalleled control and visibility.

Safety is not just a priority, it’s a necessity in warehouse and manufacturing environments. With OSHA fines on the rise, the cost of non-compliance is higher than ever. Companies are taking every measure to mitigate this risk, and iWarehouse is a powerful tool in their arsenal.

Manage and Monitor Vehicles and Operators

One impactful way iWarehouse helps in this risk mitigation is the ability to control who uses your forklift equipment. For example, let’s say operator John is only certified to drive ride-on pallet jacks; his facility badge, which now serves as a key for equipment, won’t work on the reach trucks and forklifts, only the ride-on jacks. When John’s certification is about to expire, the supervisor will be notified so his certification doesn’t lapse. If it does lapse, he won’t be able to badge into any equipment and will be using manual pump jacks until it’s renewed.

say operator John is only certified to drive ride-on pallet jacks; his facility badge, which now serves as a key for equipment, won’t work on the reach trucks and forklifts, only the ride-on jacks. When John’s certification is about to expire, the supervisor will be notified so his certification doesn’t lapse. If it does lapse, he won’t be able to badge into any equipment and will be using manual pump jacks until it’s renewed.

Fortunately for John, his renewal training was on time and included reach trucks and forklifts. He can now badge into all equipment in the facility, making him a productive, valuable and safe staff member. This level of control allows leaders to ensure only certified operators are using powered industrial vehicles, substantially reducing the chance of an incident.

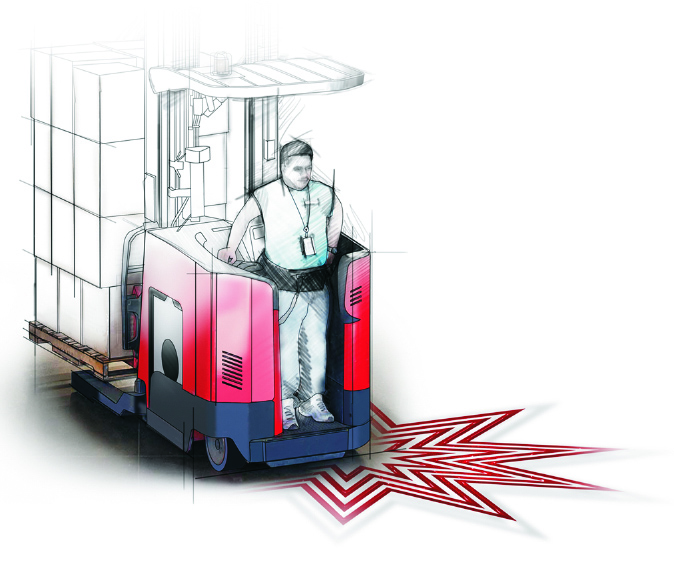

Avoid Collisions

Another significant component of safety is collision reporting. Suppose an operator collides with an obstacle, like a pallet rack. In that case, this creates environmental and equipment damage and increases the chance for a rack to become unstable and collapse, a company’s worst nightmare. As most warehouse managers know, it’s rare to have an operator fess up to driving into a rack. This makes it hard to prevent future accidents.

nightmare. As most warehouse managers know, it’s rare to have an operator fess up to driving into a rack. This makes it hard to prevent future accidents.

With iWarehouse, a collision immediately triggers an email to the supervisor, letting them know who was driving, what vehicle, and what time it happened. If it’s serious enough, it will even slow down the Raymond truck to 1mph or emit an alarm for non-Raymond trucks until the supervisor comes and unlocks the truck. Collisions go way down when operators know they are being monitored. This drastically increases safety and decreases the risk of an incident. You can also run a monthly report to see who has the least and most incidents. Now you have a good pulse on who might need more training versus a pat on the back.

Boost Efficiency with Actionable Data

Safety isn’t the only way of mitigating risk and costs. Another way is managing your fleet’s maintenance and knowing when to replace equipment versus fixing it. Companies who manage this data on their own know how cumbersome it can be to manage spreadsheets and track costs. Thankfully, with the iWarehouse module called iTrack, the software does all the heavy lifting. It tracks all costs associated with your fleet, from maintenance and repairs to avoidable damage. It even allows you to approve expensive repairs through your online portal. You can quickly check into the truck’s cost history and make a judgment call if it’s worth fixing.

The same goes with CAPEX planning. At a glance, you can look at your entire fleet and see which units fall into the recommended to-replace section based on their age, usage, and repair costs. This gives you actionable data when planning your budget. It also informs you if a unit recommended to be removed is costing you a lot and not getting much use, so you can likely do without it.

Right Size Your Fleet

iWarehouse provides all kinds of utilization reporting. With this information, you can determine if you have too many trucks and the right mix of truck types, who your best operators are and which operators need training or should be repurposed. In our experience, many fleets are oversized, even for peak. Think of how much money you can save by not only right sizing your fleet but eliminating the operators driving those unneeded trucks.

Optimize Operations

Leveraging software and control mechanisms like iWarehouse lets you manage your fleet, operators, and costs more efficiently. This gives you more time and money to do what you do best: making or distributing awesome products.

Contact your sales rep today for more information or a demo on iWarehouse today.

Leave a Reply

You must be logged in to post a comment.