In industrial settings, forklifts are pivotal in material handling. However, their power and maneuverability come with inherent risks, making forklift safety a top priority. Understanding and implementing safety measures is crucial to prevent workplace accidents and potential injuries or worse.

- Training and Certification

Before operating a forklift, employees must undergo comprehensive training and obtain the necessary certifications. Training programs cover aspects such as proper vehicle operation, load handling, and emergency procedures. Regular refresher courses can help reinforce safety protocols. Courses can be tailored to specific operating conditions and new tools like VR technology to improve both the efficacy and efficiency of your training.

Training programs cover aspects such as proper vehicle operation, load handling, and emergency procedures. Regular refresher courses can help reinforce safety protocols. Courses can be tailored to specific operating conditions and new tools like VR technology to improve both the efficacy and efficiency of your training.

- Inspections and Maintenance

Routine inspections and maintenance checks are paramount to forklift safety. Operators should inspect the vehicle before each use, focusing on brakes, steering, tires, and hydraulics. Telematics can ensure that OSHA-mandated daily checklists are adhered to and provide digital record storage. When an issue is uncovered, be sure to use a well-trained service department to diagnose and repair issues promptly to prevent potential malfunctions.

- Load Management

Understanding load capacity is essential to avoid overloading the forklift. Train operators to accurately assess the weight of loads and both horizontal and vertical load centers and secure loads properly. Mismanagement of loads can lead to instability, tipping, or loss of control.

- Operating Environment Awareness

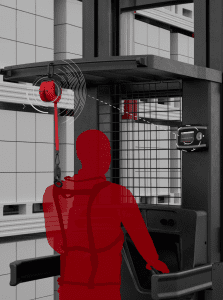

A safe working environment is vital for forklift operations. Clear and well-lit pathways, marked pedestrian zones, and designated areas for loading and unloading contribute to a secure workplace. Adequate signage and communication systems help minimize the risk of collisions. Leading technologies such as Object Sense can greatly mitigate collisions and Smart Tethers can preclude orderpickers from operating their vehicles unless they’re tethered in.

A safe working environment is vital for forklift operations. Clear and well-lit pathways, marked pedestrian zones, and designated areas for loading and unloading contribute to a secure workplace. Adequate signage and communication systems help minimize the risk of collisions. Leading technologies such as Object Sense can greatly mitigate collisions and Smart Tethers can preclude orderpickers from operating their vehicles unless they’re tethered in.

- Speed Control

Maintaining a controlled speed is crucial for forklift safety. Operators should adhere to speed limits and adjust their speed according to the load, terrain, and visibility conditions. Sudden accelerations or abrupt stops can lead to accidents.

- Seatbelt Usage

Wearing seatbelts may seem like a simple precaution, but it is a crucial element of forklift safety. Seatbelts can prevent operators from being ejected during a tip-over or collision, significantly reducing the risk of serious injury.

- Emergency Response Plan

Having a well-defined emergency response plan is essential for any workplace. This includes procedures for dealing with accidents, medical emergencies, or equipment malfunctions. Regular drills and training sessions ensure employees are well-prepared to handle unexpected situations.

Commit to forklift safety

Abel Womack strives to help organizations with forklift safety for operators and employees. By prioritizing training, technology, and maintenance and creating a culture of awareness, workplaces can significantly reduce the risk of accidents and foster a secure environment for all. Remember, a commitment to forklift safety protects individuals and contributes to increased productivity and overall operational efficiency.

Leave a Reply

You must be logged in to post a comment.